DME XPress Delivery

Don’t Sacrifice Quality for Speed!

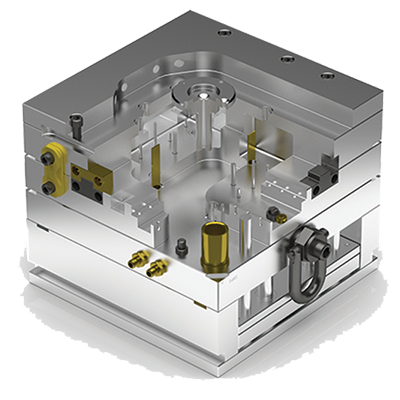

The DME XPress™ delivery mold bases sets the standard for rapid shipment with online configuration of 58,000 combinations.

Featuring:

XPress Mold Bases Family

Check out the exciting XPress A-Seiries, B-Series and Stainless Steel A-Series and B-Series . Click Here

XPress CAD Data

Need CAD data for XPress Mold Bases Click Here to visit the DME Configurator to build, download CAD and order on-line.

Purchase on DME eStore

Only at DME

Quick Ship

Precision Interchangeable Plates

Fully Featured

DME Quality

Configure your XPress Mold Base and Download CAD

Click Here

DME XPress A & B-Series

Series Benefits:

Ready to Ship!

- Rapid shipment

- Interchangeable plates

- Configurable mold base

- Precision machined

- Repeatable

- Replacement plates online and easy to order

- 58,000 configurations

- Engineered and validated

Stress Relieved & Pre-Hardened Steel

- DME #3 premium P20 steel – “Machined-4-Quality”

- Increases your cutting speeds

- Reduces machine center spindle time

- Avoid unnecessary downtime

- Extended tool life

DME XPress A-Series

Features:

Standard Mold Base Features Include:

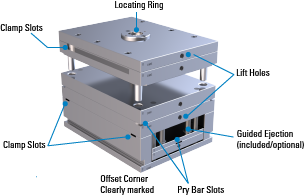

- 7 Plate A-Series Design

- 23 Sizes – 8”x 8” to 19”x 24”

- 9 A/B-Plate thicknesses – 7/8” to 5-7/8”

- 162 A/B-Plate combinations

- Rail Heights 2.5”- 4.5”

- #3 Premium P20 steel for A and B-Plates

- Steel Finish Ground ± .001”

- Center Holes – A-side only (optional)

- Return Pins – inboard (prevents spring breakout)

- Locating Ring (optional)

- Sprue Bushing (optional)

- Lift Holes – 5 plates

- Vented Leader Pins

- Clamp Slots

- Pry Bar Slots on parting line and ejector plate

- Chamfering on all plate edges

- Stop Disks

- 3-Piece Ejector Housing with shoulder bolts

DME XPress B-Series

Features:

Standard Mold Base Features Include:

- 5 Plate B-Series Design

- 23 Sizes – 8”x 8” to 19”x 24”

- 7 AC/B-Plate thicknesses – 7/8” to 5-7/8”

- 126 AC/B-Plate combinations

- Rail Heights 2.5”- 4.5”

- #3 Premium P20 steel for AC and B-Plates

- Steel Finish Ground ± .001”

- Center Holes – A-side only (optional)

- Guided Ejection – system #3 (optional)

- Return Pins – inboard (prevents spring breakout)

- Locating Ring (optional)

- Sprue Bushing (optional)

- Vented Leader Pins

- Clamp Slots

- Pry Bar Slots on parting line and ejector plate

- Chamfering on all plate edges

- Stop Disks

- 3-Piece Ejector Housing with shoulder bolts

XPress SS – Stainless Steel

Stress Relieved & Pre-Hardened Steel

- Increases your cutting speeds

- Reduces machine center spindle time

- Avoid unnecessary downtime

- Extended tool life

- DME #7 premium stainless steel – “Machined-4-Quality”

- Interchangeable plates

- Precision machined

- Repeatable

- Replacement plates, online and easy to order

- Engineered and validated

- XPress rapid shipment

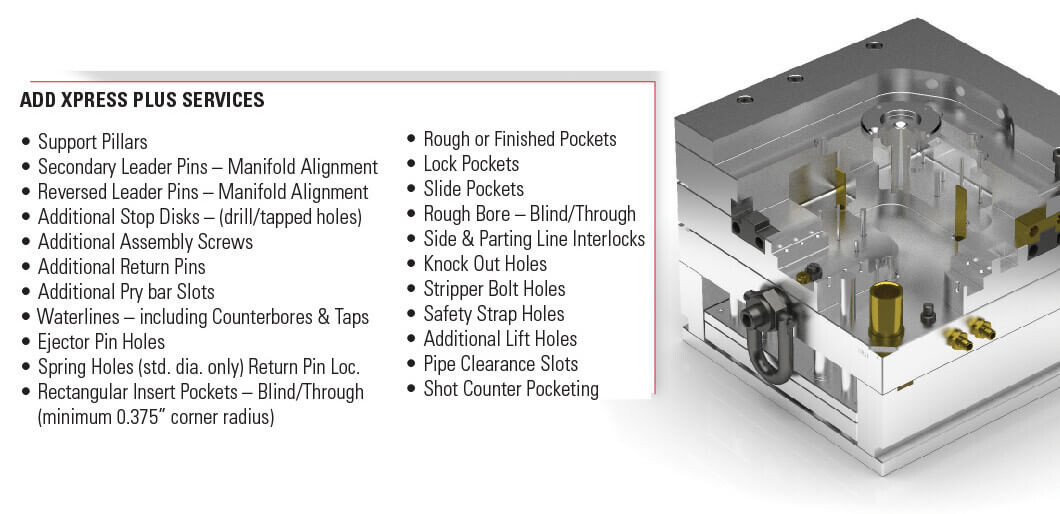

Take it to the Next Level with XPress Plus

DME XPress PLUS offers the XPress mold base features, plus additional services to meet your needs and a 50% faster lead time than the industry standard.

See more information on DME XPress PLUS below.

Stainless A-Series Mold Base Features Include:

- 7 Plate A-Series Design

- 8 Sizes – 8”x 8” to 13”x 21”

- 4 A/B-Plate thicknesses – 1-3/8” to 2-7/8”

- 16 A/B-Plate combinations

- Rail Heights 3” or 4”

- #7 Premium 420 stainless steel (top to bottom)

- Guided Ejection

- 3-Piece Ejector Housing with shoulder bolts

- Center Holes – A-side only (optional)

Features:

- Steel Finish Ground ± .001”

- Guided Ejection – system #3 (optional)

- Return Pins – inboard (prevents spring breakout)

- Locating Ring (optional)

- Sprue Bushing (optional)

- Vented Leader Pins

- Clamp Slots

- Pry Bar Slots on parting line and ejector plate

- Chamfering on all plate edges

- Stop Disks

- 3-Piece Ejector Housing with shoulder bolts

DME XPress Plus

DME XPress™ Plus offers the XPress mold base features, plus additional services to meet your needs at a 50% faster lead time than the industry standard.